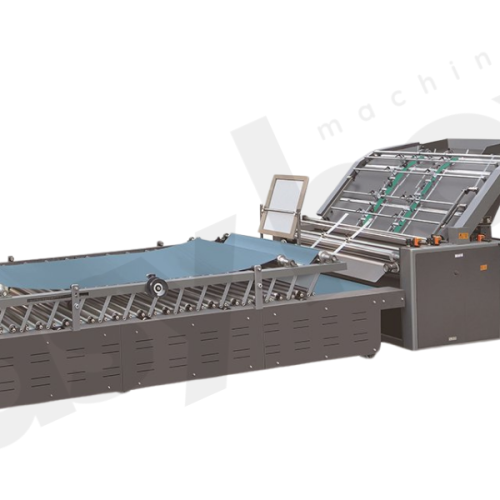

MHK 3S1050TRMC TRIOPRESS آلة قطع القوالب والختم الساخن الأوتوماتيكية عالية السرعة مع نظام التجريد والتدفئة

(+86) 158 9968 3398 دردشة واتس اب

Product Description

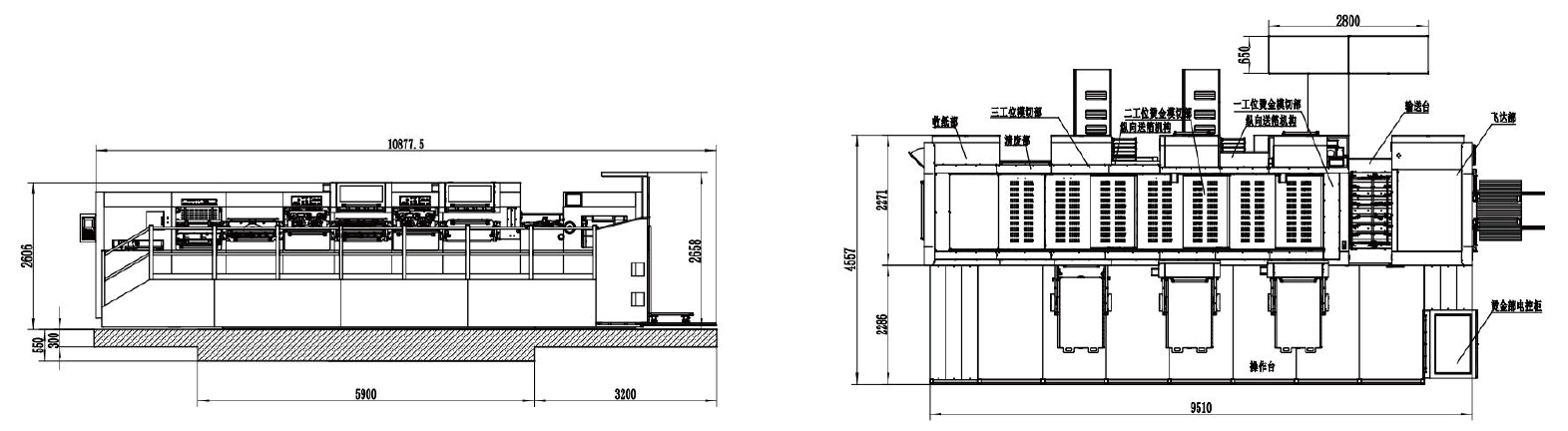

رسم

MHK 3S1050TRMC TRIOPRESS Automatic High Speed Hot Stamping & Die Cutting Machine with Stripping & Heating System: Efficiency and Precision in One Pass

The MHK 3S1050TRMC TRIOPRESS Automatic High Speed Hot Stamping & Die Cutting Machine with Stripping & Heating System is a state-of-the-art solution designed for the high demands of modern post-press operations. By integrating multiple processes into a single seamless operation, this machine offers exceptional precision, efficiency, and reliability.

الميزات والفوائد الرئيسية

One-Pass Multi-Process Capability

The MHK 3S1050TRMC TRIOPRESS can perform multiple processes in one pass, significantly enhancing production efficiency and reducing labor costs. The machine’s capabilities include:

- Hot Stamping + Deep Embossing + Die Cutting + Stripping: Achieve intricate and high-quality foil designs, deep embossing, precise die cutting, and efficient stripping in a single operation.

- Deep Embossing + Deep Embossing + Die Cutting + Stripping: Combine multiple deep embossing processes with die cutting and stripping for superior texture and detail.

Precision and Efficiency

The MHK 3S1050TRMC TRIOPRESS stands out with its ability to accurately register multiple processes in one pass, a capability that traditional machines often cannot match. This precision ensures high-quality results and maximizes production efficiency.

Robust Construction and Design

Constructed from high-quality materials, the MHK 3S1050TRMC is built for durability and stability. Its heavy-duty construction guarantees reliable performance under continuous operation, making it suitable for high-volume production tasks.

واجهة سهلة الاستخدام

The machine features an intuitive user interface, allowing operators to easily set up and adjust parameters, monitor the production process, and troubleshoot issues. This user-friendly design enhances productivity and reduces the learning curve for new operators.

Advanced Heating System

The integrated heating system ensures consistent and precise temperature control, which is essential for high-quality hot stamping and deep embossing. This feature enhances the machine’s overall reliability and performance, ensuring uniform results across all production runs.

Efficient Stripping System

The efficient stripping system automatically removes waste material, streamlining the production process and reducing the need for manual intervention. This feature increases efficiency, ensures a cleaner production environment, and enhances the overall quality of finished products.

Safety Features

Safety is a top priority with the MHK 3S1050TRMC. The machine is equipped with multiple safety mechanisms, including emergency stop buttons, safety guards, and sensors that detect and respond to potential hazards, ensuring safe operation for all users.

تطبيقات متعددة الاستخدامات

The MHK 3S1050TRMC is versatile and can handle a wide range of materials, including paper, cardboard, plastic sheets, and more. Its adaptability makes it an excellent choice for various industries, including:

- الطباعة: Delivering high-quality stamping, embossing, and cutting for printed materials.

- التعبئة والتغليف: Providing precise die-cutting, foil stamping, and stripping for packaging materials.

- Labels and Tags: Creating detailed and attractive designs for labels and tags.

- Decorative Applications: Enhancing decorative items with intricate cuts, foil accents, and embossing.

تعزيز الإنتاجية

The integration of high-speed operation, hot stamping, deep embossing, die cutting, and stripping functions in a single machine enhances overall productivity. This combination reduces downtime, minimizes manual intervention, and ensures consistent quality across all production runs.

تقدمات تكنولوجية

The MHK 3S1050TRMC TRIOPRESS incorporates advanced technological features, including servo precision control systems and automated functions. These innovations streamline the production process, reduce downtime, and enhance efficiency, making this machine a valuable asset for modern manufacturing operations.

خاتمة

The MHK 3S1050TRMC TRIOPRESS Automatic High Speed Hot Stamping & Die Cutting Machine with Stripping & Heating System offers a superior combination of precision, speed, and advanced automation. Its robust construction, user-friendly interface, and versatile applications make it an excellent investment for businesses looking to enhance their post-press processes. Whether for printing, packaging, or decorative applications, the MHK 3S1050TRMC delivers exceptional performance and reliability, meeting the high demands of today’s industrial environments.

مقدمة جزئية

وحدة التغذية

أربعة رؤوس للالتقاط وأربعة رؤوس ماصة للأمام مع إمكانية تعديل الزاوية للتعامل مع أنواع مختلفة من المواد.

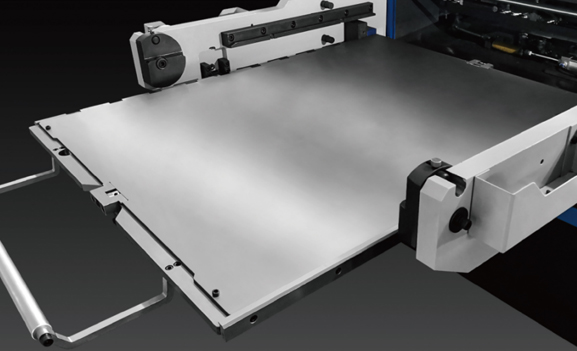

طاولة التغذية

جهاز مزامنة لضبط موضع الورقة على الوضع الأمامي يدويًا أثناء الإنتاج، جهاز تثبيت الورقة (توجيه الأوراق إلى الطبقات الأمامية).

Hot stamping section

Heating base with 20 heating zone each temperature adjustable individually for efficient and accurate temperature control.

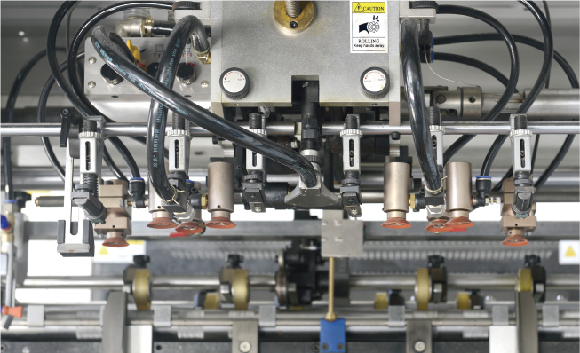

Foil advancing unit

Three sets of longitudinal foil advancing shafts and two sets of lateral foil advancing shafts are driven by servo motors individually programmable for short and long foil stepping.

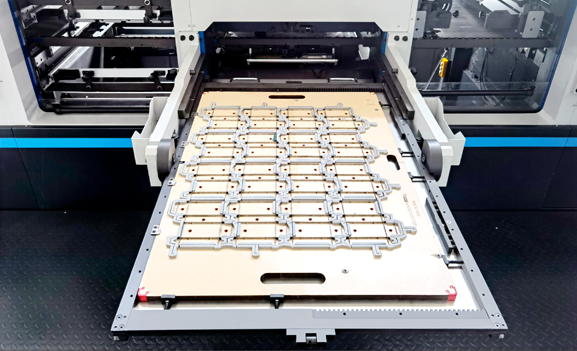

Mould quick locking device

Adopt Center-line system and quick locking device to save make ready time.

Plate setting

5mm hardened stamping plate or 3.5mm + 1.5mm sandwich stamping plate on top of 15mm precision ground supporting base plate with +/-0.9mm micro adjustment in both running and cross direction for quick set up and easy make ready.

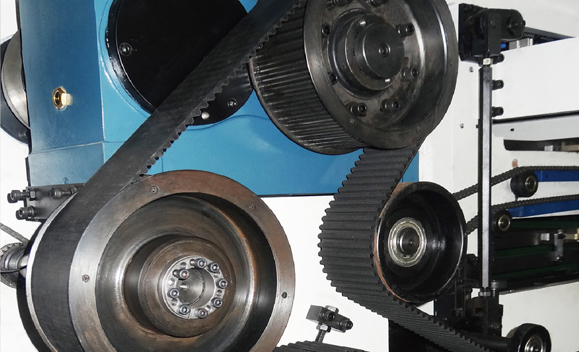

Torque limiter

تضمن التجزئة المتقطعة عالية الدقة في تايوان دقة موضعية عالية للاستخدام لفترة طويلة.

Taiwan torque limiter can accurately protect the artificial operation accident to guarantee the people and machine safety by its sensitive limit protection performance.

Main motor lubrication system

Taiwan made automatic oil pump cooling circulation system to ensure main motor lubrication of high speed for a long time.

Equipped with oil pressure gauge and with oil pressure alarm device.

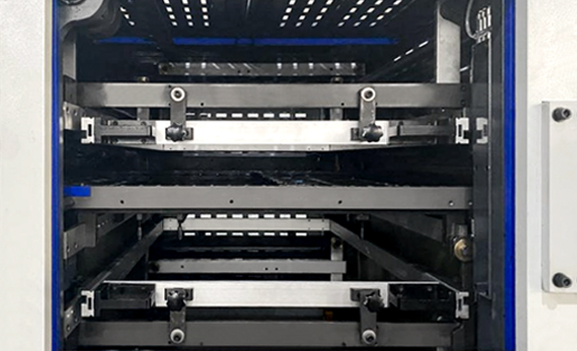

وحدة التجريد

اعتماد نظام الخط المركزي، يمكن سحب إطار تثبيت أداة التجريد العلوي والسفلي لإعداد المهمة والاستعداد.

Gripper edge waste removal device

Gripper edge stripping and removing system with conveyor belt to remove the gripper edge waste sideways to the drive side.

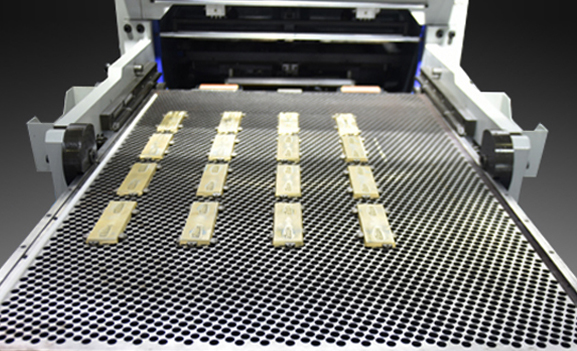

Delivery unit

تسليم تلقائي مع ستارة بدون توقف. تتحرك هذه الستارة إلى مكان التسليم لالتقاط الأوراق القادمة أثناء تبادل الأكوام. يمكن أن يضمن منفاخان لتجميع الورق تجميعًا أنيقًا للأوراق الرفيعة والسميكة.

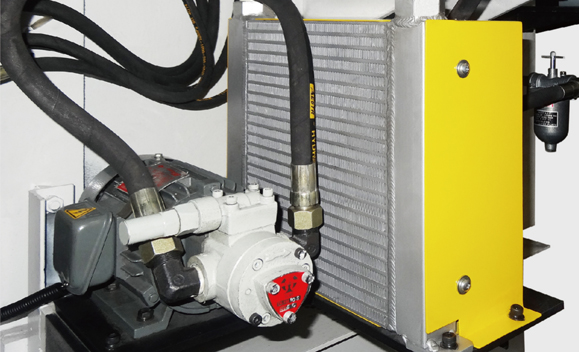

Germany vaccum pump

Germany Becker oil free blower and vacuum pump.

نظام التشحيم التلقائي

اعتماد نظام التشحيم التلقائي المركز للتأكد من أن الأجزاء المدفوعة تعمل بشكل أفضل.

Machine Parameters

| نموذج | MHK-3S1050TRMC |

|---|---|

| Function | 1. hot stamping+deep embossing+die cutting+stripping |

| الحد الأقصى لحجم الورقة | 1050×750 ملم |

| الحد الأدنى لحجم الورقة | 400×360mm |

| الحد الأقصى لحجم القطع | 1040×720 ملم |

| Max. Hot Stamping Size | 1040×720 ملم |

| الأعلى. منطقة النقش | 1040×720 ملم |

| الحد الأدنى لهامش القابض | 9~17mm |

| حجم المطاردة الداخلي | 1140×755mm |

| نطاق المخزون | Paper: from 80 to 2000g/m2, 0.1~2mm, corrugated board: up to 4mm |

| دقة قطع القالب | ≤±0.075mm |

| Common Stamping Accuracy | ≤±0.075mm |

| Hologram Positioning Stamping Accuracy | ≤±0.075mm(optional) |

| دقة النقش | ≤±0.075mm |

| Max. Die Cutting Force | Press1: 600T, Press2: 600T, Press3: 300T |

| سرعة العمل القصوى | 6200s/h (Die cutting), 6200s/h (Hot stamping), 6200s/h (Hot pressing) |

| الأعلى. ارتفاع كومة التغذية | 1600mm(With wooden pallet) |

| الأعلى. ارتفاع كومة التسليم | 1400mm(With wooden pallet) |

| Max. Gold Foil Diameter | Ф250mm Longitudinal, Ф200mm Transversal |

| نظام تسخين كهربائي | 20 نطاقًا لدرجة الحرارة، 40-180 درجة مئوية قابلة للتعديل |

| Foil Width | 20~1020mm |

| Press1 Foil Advance Shafts | 3 Longitudinal+2 Transversal (optional) |

| Press2 | Equipped with electric heating system |

| Press3 | die cutting+stripping |

| أبعاد الآلة | 10878×4557×2658mm(L×W×H) (L: paper prepared track included, W: platform included) |

| الوزن الصافي للآلة | 44T |

| القدرة الكهربائية الكاملة للحمل | 99KW |

| متطلبات الهواء | Pressure: 0.6~0.7Mpa, Flow: ≥1m3/min |

المراجعات

لا توجد مراجعات بعد.