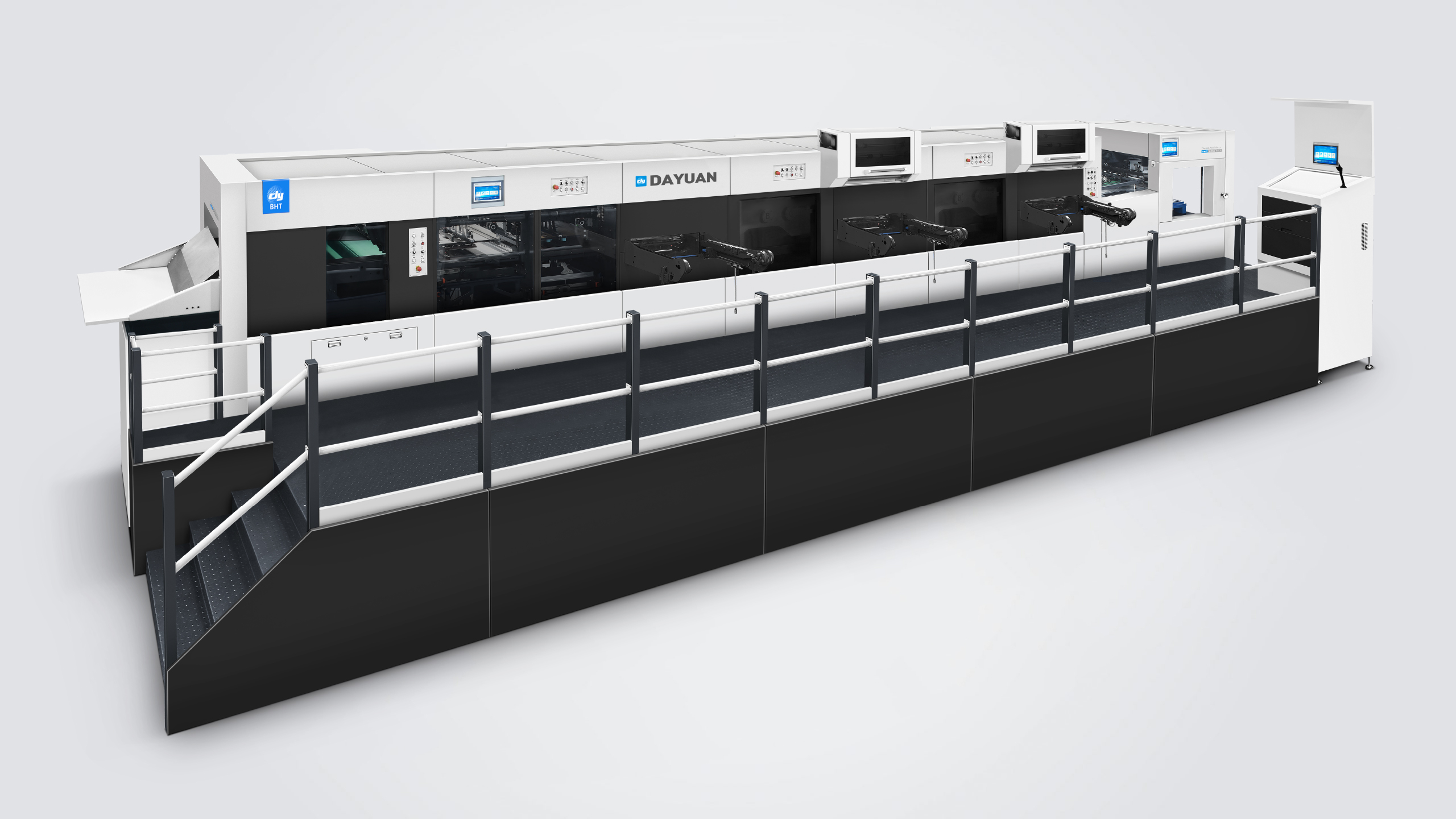

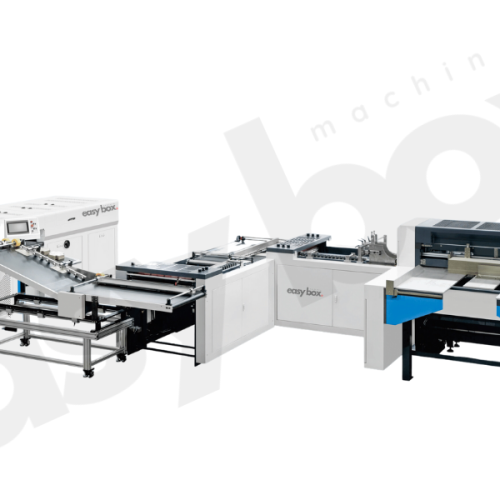

BHT 3S1060TTMSCE TRIOPRESS Automatic High Speed Double Hot Stamping & Die Cutting Machine with Stripping & Blanking

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 دردشة واتساب

Product Description

BHT 3S1060TTMSCE TRIOPRESS Automatic High Speed Double Hot Stamping & Die Cutting Machine with Stripping & Blanking: Superior Efficiency and Precision

The BHT 3S1060TTMSCE TRIOPRESS is an advanced, high-speed machine designed for double hot stamping and die cutting, equipped with stripping and blanking capabilities. This cutting-edge equipment offers exceptional precision, efficiency, and versatility, making it ideal for industries that demand high-quality finishing processes.

الميزات والفوائد الرئيسية

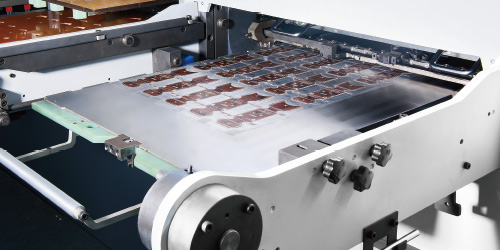

Double Hot Stamping

The BHT 3S1060TTMSCE features a double hot stamping system, enabling intricate and high-quality foil designs on various materials. This dual stamping capability enhances the aesthetic appeal of products, making it perfect for luxury packaging, high-end labels, and decorative items.

Precision Die Cutting

With its advanced die-cutting mechanism, this machine ensures clean, accurate cuts every time. The precision die cutting feature is crucial for applications requiring detailed and flawless finishes, such as in the printing, packaging, and decorative industries.

تشغيل عالي السرعة

The TRIOPRESS BHT 3S1060TTMSCE is designed for high-speed production, significantly increasing throughput and reducing lead times. This high-speed capability is essential for large-scale production environments, ensuring efficient and timely delivery of finished products.

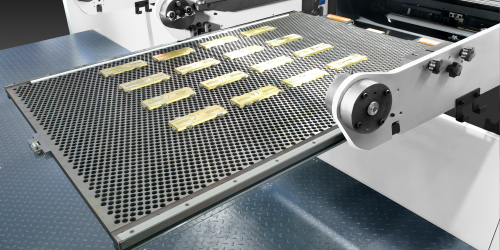

Stripping and Blanking Capabilities

Integrated stripping and blanking features streamline the production process by automatically removing waste and separating finished products from scrap. This automation reduces manual labor, increases efficiency, and ensures a cleaner production environment.

Robust Construction

Built with high-quality materials, the BHT 3S1060TTMSCE is designed for durability and stability. Its heavy-duty construction ensures reliable performance under continuous operation, making it suitable for high-volume production tasks.

واجهة سهلة الاستخدام

تتميز الماكينة بواجهة مستخدم سهلة الاستخدام، مما يسمح للمشغلين بإعداد وتعديل المعلمات ومراقبة عملية الإنتاج واستكشاف المشكلات وإصلاحها بسهولة. يعمل هذا التصميم سهل الاستخدام على تعزيز الإنتاجية وتقليل منحنى التعلم للمشغلين الجدد.

ميزات السلامة

Safety is a top priority in the design of the BHT 3S1060TTMSCE. The machine is equipped with multiple safety mechanisms, including emergency stop buttons, safety guards, and sensors that detect and respond to potential hazards, ensuring safe operation for all users.

تطبيقات متعددة الاستخدامات

The BHT 3S1060TTMSCE is versatile and can handle a wide range of materials, including paper, cardboard, plastic sheets, and more. Its adaptability makes it an excellent choice for various industries, including:

- الطباعة: Delivering high-quality stamping and cutting for printed materials.

- التغليف: Providing precise die-cutting and foil stamping for packaging materials.

- العلامات والعلامات: إنشاء تصميمات مفصلة وجذابة للملصقات والعلامات.

- التطبيقات الزخرفية: Enhancing decorative items with intricate cuts and foil accents.

زيادة الإنتاجية

The integration of high-speed operation, double hot stamping, die cutting, stripping, and blanking functions in a single machine enhances overall productivity. This combination reduces downtime, minimizes manual intervention, and ensures consistent quality across all production runs.

التقدم التكنولوجي

The BHT 3S1060TTMSCE TRIOPRESS stands out with its advanced technological features, including servo precision control systems and automated functions. These innovations streamline the production process, reduce downtime, and enhance efficiency, making this machine a valuable asset for modern manufacturing operations.

خاتمة

The BHT 3S1060TTMSCE TRIOPRESS Automatic High Speed Double Hot Stamping & Die Cutting Machine with Stripping & Blanking offers a superior combination of precision, speed, and advanced automation. Its robust construction, user-friendly interface, and versatile applications make it an excellent investment for businesses looking to enhance their finishing processes. Whether for printing, packaging, or decorative applications, the BHT 3S1060TTMSCE delivers exceptional performance and reliability, meeting the high demands of today’s industrial environments.

مقدمة جزئية

وحدة التغذية

Feeder based on advanced technical platform feeding precisely and consistently of wide range stock from 90g/m2 thin paper to 1000g/m2 cardboard as well as micro flute corrugated board.

كاشف الورقة المزدوجة

كاشف الورقة المزدوجة بالموجات فوق الصوتية دون لمس الورقة، وبالتالي خالية من الخدوش، وإعداد موثوق وسريع.

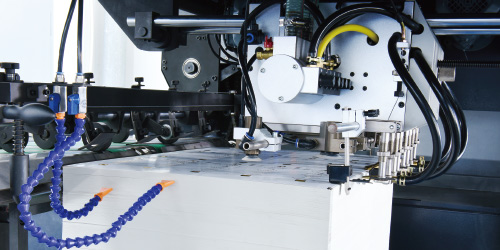

شريط القابض

Gripper bars made of cutting edge latest technology running extremely smoothly, thanks to the unique design of large motion angle eccentric worm gear drive system.

قسم الختم الساخن

Max stamping pressure up to 600 tons, which makes it able to achieve better 3D and exquisite effect on large format printing materials such as wine boxes and cigarette boxes.

ضبط اللوحة

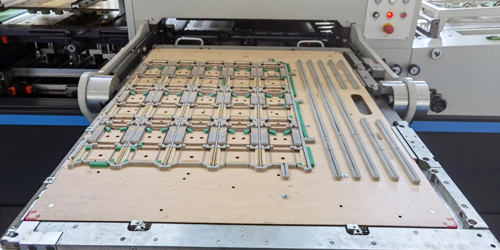

لوحة قطع صلبة 5 مم أو لوحة شطيرة 4+1 مم في الأعلى، لوحة دعم صناعية دقيقة 15 مم مع تعديل دقيق +/-0.9 مم للإعداد السريع والتحضير السهل.

جهاز قفل سريع للقالب

اعتماد نظام خط الوسط وجهاز القفل السريع لتوفير وقت الاستعداد.

قفل الأدوات المتقدمة

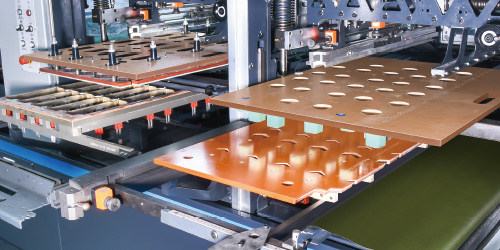

Advanced quick tooling set up system ensures fast job change over and hence high productivity at both stripping and blanking stations.

Full sheet delivery

Full sheet delivery option to ensure easy production planning by selecting final delivery style.

Auto separation sheet insert

Automatic separating sheet inserter oupled with electronic position sensor at blanking station.

Non-stop sampling

The Sampling Function can be used to remove a sample sheet on the fly by one button only, easy for operating.

مضخة فراغ المانيا

منفاخ ومضخة تفريغ خالية من الزيت من ألمانيا Becker.

نظام التشحيم التلقائي

اعتماد نظام التشحيم التلقائي المركز للتأكد من أن الأجزاء المحركة تعمل بشكل أفضل.

Machine Parameters

| نموذج | BHT-3S1060TTMSCE |

|---|---|

| وظيفة | 1. hot stamping+hot stamping+die cutting+stripping+blanking |

| الحد الأقصى لحجم الورقة | 1060×760 مم |

| الحد الأدنى لحجم الورقة | 400×350 مم |

| الحد الأقصى لحجم القطع | 1060×745 ملم |

| Maximum Stamping Size | 1060×740mm |

| الحد الأدنى لهامش القابض | 9~17 ملم |

| حجم المطاردة الداخلية | 1080×770 مم |

| مجموعة الأسهم | Paper: from 80 to 2000g/m2, 0.1~2mm, |

| دقة القطع بالقالب | ≤±0.075 مم |

| دقة الختم المشتركة | ≤±0.075 مم |

| دقة ختم تحديد موقع الهولوغرام | ≤±0.075 مم |

| Max.die Cutting Force | اضغط 1: 600T، اضغط 2: 600T، اضغط 3: 300T |

| الحد الأقصى لسرعة العمل | 6200s/h |

| Maximum Pile Height at Feeder-Normal Mode | 1800 ملم |

| Maximum Pile Height at Feeder-Non-stop Mode | 1520mm |

| أقصى ارتفاع للكومة عند التسليم | 1580mm |

| Max.gold Foil Diameter | Φ250mm Longitudinal; Φ200mm Transversal |

| نظام التدفئة الكهربائية | 20 Heating zones, 40~180℃Adjustable |

| عرض الرقاقة | 20~1060mm |

| أعمدة التقدم من شركة Press1 Foil | 3 Longitudinal + 2 Transversal (Optional) |

| أعمدة تقدمية من شركة Press2 Foil | 3 Longitudinal + 2 Transversal (Optional) |

| الصحافة 3 | die cutting+stripping |

| أبعاد الماكينة | 14078×5857×2657mm (L×W×H) |

| الوزن الصافي للآلة | 52000kg |

| قوة الحمل الكاملة | 145KW |

| متطلبات الهواء | Pressure: 0.6~0.7Mpa, Flow: ≥1m3/min |

المراجعات

لا توجد مراجعات بعد.