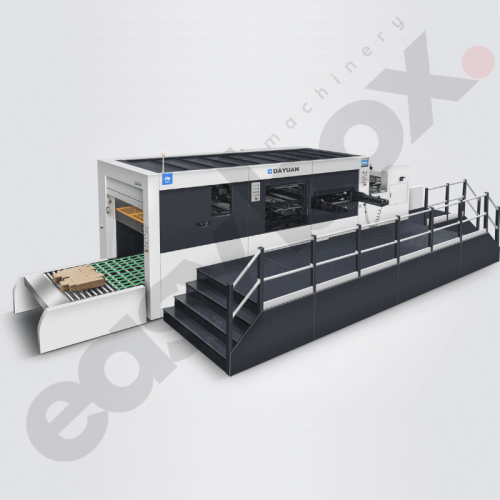

آلة قطع وتجعيد أوتوماتيكية BHT 1060CE مع التجريد

Did you like this product? Add to favorites now and follow the product.

(+86) 158 9968 3398 دردشة واتساب

Product Description

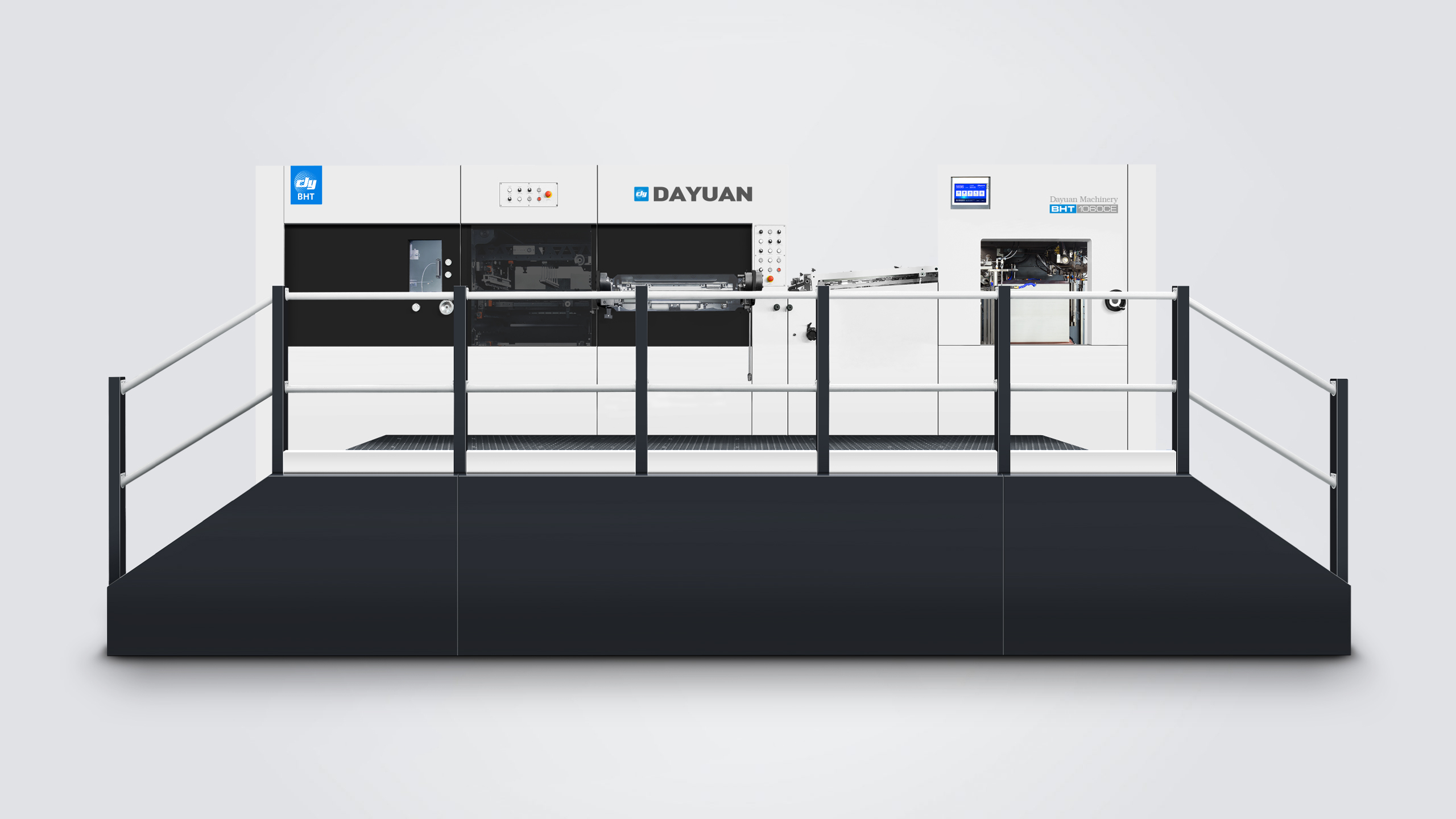

Introduction to the BHT 1060CE Automatic Die Cutting and Creasing Machine with Stripping

The BHT 1060CE Automatic Die Cutting and Creasing Machine with Stripping is an advanced solution designed for precision and efficiency in the packaging and printing industries. This machine integrates die cutting, creasing, and stripping functionalities into a single, streamlined system, making it an essential asset for modern manufacturing environments.

الميزات الرئيسية

دقة عالية وإتقان

The BHT 1060CE ensures millimeter-perfect die cutting and creasing, ideal for applications requiring detailed and exact specifications. This high level of precision minimizes material waste and enhances overall product quality.

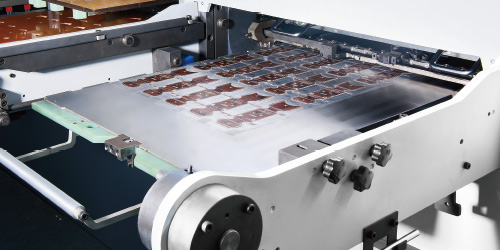

وظيفة التجريد المتكاملة

One of the standout features of the BHT 1060CE is its integrated stripping functionality. This system automatically removes waste material, ensuring clean and precise edges, reducing manual labor, and speeding up the production process.

أداء عالي السرعة

Designed for high-speed operations, the BHT 1060CE significantly boosts productivity. Its robust construction and advanced technology allow it to handle large-scale production efficiently, meeting tight deadlines without compromising on accuracy.

فوائد

- كفاءة محسنة: The automatic feeder and delivery system streamline the workflow from start to finish, reducing downtime and labor costs.

- واجهة سهلة الاستخدام: An intuitive touch-screen display provides easy setup and real-time monitoring, minimizing the learning curve for operators and ensuring smooth operation.

- ميزات السلامة: Equipped with emergency stop buttons and protective guards, the machine ensures a safe working environment, adhering to the highest industry standards.

التطبيقات

The BHT 1060CE is perfect for a variety of applications, including packaging, labels, signage, and custom print materials. Its versatility, precision, and integrated stripping function make it a valuable asset for businesses looking to optimize their production processes and meet high-volume demands.

خاتمة

The BHT 1060CE Automatic Die Cutting and Creasing Machine with Stripping sets a new standard in the industry with its combination of precision, speed, and efficiency. Designed to meet the demands of modern manufacturing, it helps businesses increase productivity while maintaining high quality and safety standards.

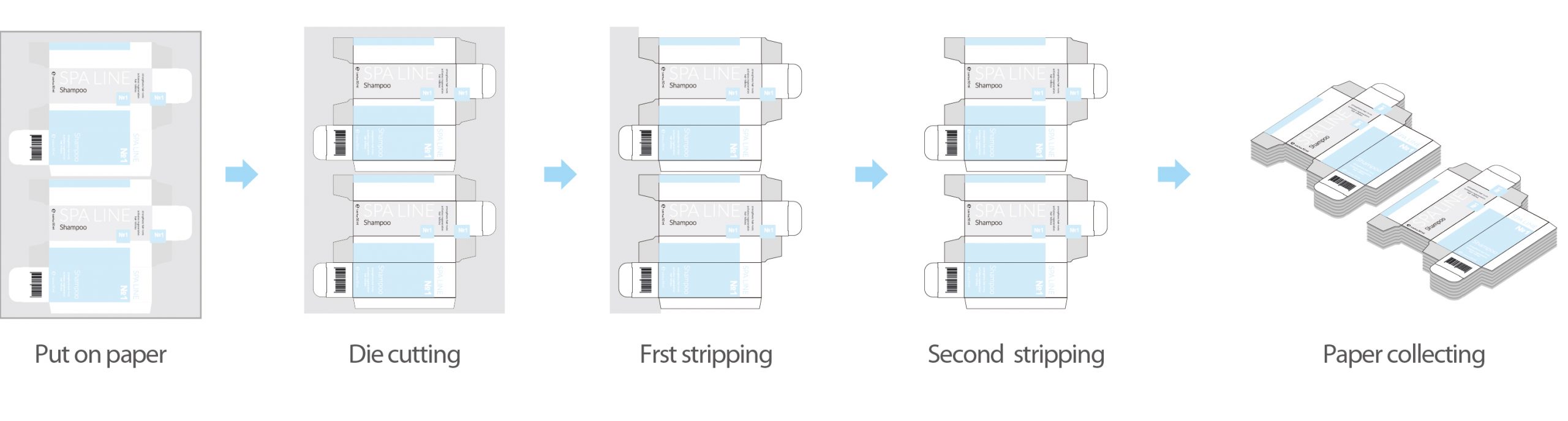

تدفق العملية

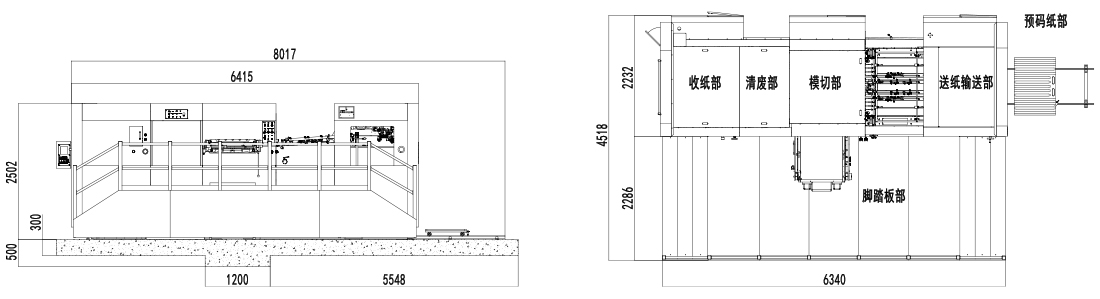

رسم

مقدمة جزئية

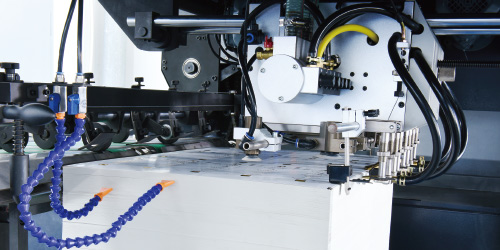

وحدة التغذية

وحدة تغذية تعتمد على منصة تقنية متقدمة تعمل على تغذية مجموعة واسعة من المخزون بدقة وبشكل مستمر من الورق الرقيق 90 جرام/م2 إلى الورق المقوى 1000 جرام/م2 بالإضافة إلى الكرتون المموج ذي الفلوت الصغير.

كاشف الورقة المزدوجة

كاشف الورقة المزدوجة بالموجات فوق الصوتية دون لمس الورقة، وبالتالي خالية من الخدوش، وإعداد موثوق وسريع.

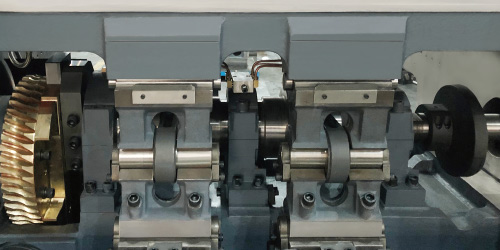

شريط القابض

7 قضبان قبضة مصنوعة من أحدث التقنيات المتطورة تعمل بسلاسة كبيرة، وذلك بفضل التصميم الفريد لنظام محرك الدودة اللامركزية بزاوية الحركة الكبيرة.

Variable speed worm gear drive device

Worm gear and toggle mechanism allows large motion angle hence minimum number and size of nicks at reasonable max. production speed.

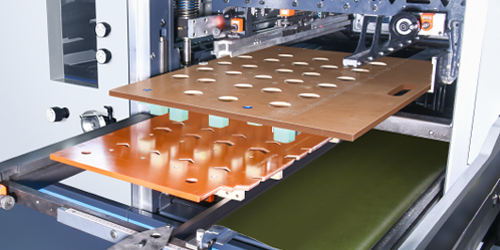

ضبط اللوحة

لوحة قطع صلبة 5 مم أو لوحة شطيرة 4+1 مم في الأعلى، لوحة دعم صناعية دقيقة 15 مم مع تعديل دقيق +/-0.9 مم للإعداد السريع والتحضير السهل.

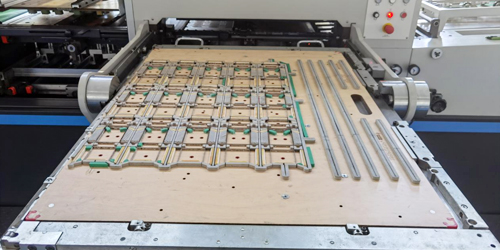

جهاز قفل سريع للقالب

اعتماد نظام خط الوسط وجهاز القفل السريع لتوفير وقت الاستعداد.

قفل الأدوات المتقدمة

يضمن نظام الإعداد السريع للأدوات المتقدم تغييرًا سريعًا للوظيفة وبالتالي إنتاجية عالية في كل من محطات التجريد.

جهاز إزالة النفايات من حافة المقبض

نظام تجريد وإزالة حافة المقبض مع حزام ناقل لإزالة نفايات حافة المقبض جانبيًا إلى جانب القيادة.

جهاز تجميع تلقائي بدون توقف

يتم التبديل بين جهاز التجميع الرئيسي وجهاز التجميع التلقائي المستمر تلقائيًا دون أي عملية، مما يجعل الماكينة أكثر كفاءة.

مضخة فراغ المانيا

منفاخ ومضخة تفريغ خالية من الزيت من ألمانيا Becker.

نظام التشحيم التلقائي

اعتماد نظام التشحيم التلقائي المركز للتأكد من أن الأجزاء المحركة تعمل بشكل أفضل.

Machine Parameters

| نموذج | BHT-1060CE |

|---|---|

| الحد الأقصى لحجم الورقة | 1060×760 مم |

| الحد الأدنى لحجم الورقة | 400×350 مم |

| الحد الأقصى لحجم القطع | 1060×745 ملم |

| الحد الأدنى لعرض القطع المزدوجة | 5 مم |

| الحد الأدنى لهامش القابض | 9~17 ملم |

| ارتفاع قاعدة القطع | 23.8 ملم |

| حجم المطاردة الداخلية | 1080×770 مم |

| مجموعة الأسهم | الورق: من 80 إلى 2000 جم/م2، 0.1~2 مم، الكرتون المموج: حتى 4 مم |

| دقة القطع بالقالب | ≤±0.075 مم |

| Max.die Cutting Force | 300 طن |

| الحد الأقصى لسرعة العمل | 9000s/h |

| Max. feeder pile height | 1630mm(With wooden pallet) |

| Max. delivery pile height | 1480mm(With wooden pallet) |

| أبعاد الماكينة | 8017×4518×2502mm (L×W×H) (L: paper prepared track included, W: platform included) |

| الوزن الصافي للآلة | 18000kg |

| قوة المحرك الرئيسي | 15 كيلو وات |

| إجمالي الطاقة المطلوبة | 23 كيلو وات |

| متطلبات الهواء | Pressure: 0.6~0.7Mpa, Flow: ≥0.37m3/min |

المراجعات

لا توجد مراجعات بعد.